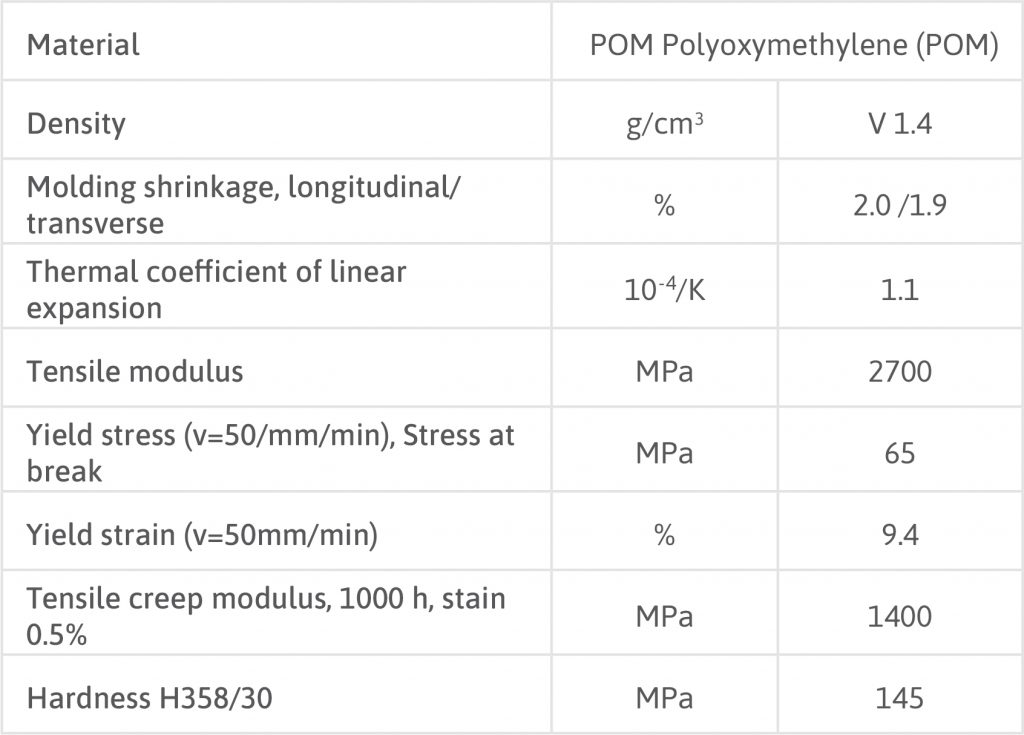

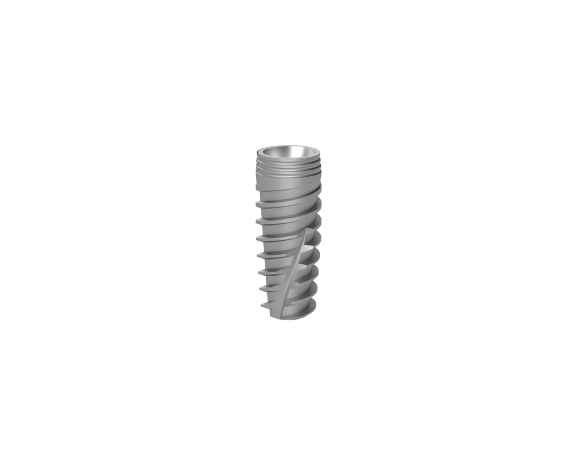

Here at Edison Medical™ we use injection molding technologies in order to produce our burnout products. Through this unique process we provide a high quality surface finish on our castable abutment products. During this procedure we use Polyoxymethylene (Also known as POM or Acetal), providing a cheaper option to that of the Chrome Cobalt / Gold UCLA abutments.

When the materials melt during the burnout process, this allows them to melt without leaving any debris. These materials are ideal for creating highly precise full partials for direct investment casting. Another possibility is to produce multiple unit bridges with a accurate fit. Burnouts are a homogeneous bending resistant thermoplastic material which is used in the casting process. Materials used in this procedure for the castable abutment needs to be selected as to compensate for the dimensional modification that occur during the casting investment, which includes setting expansion & shrinkage of the casting investment.

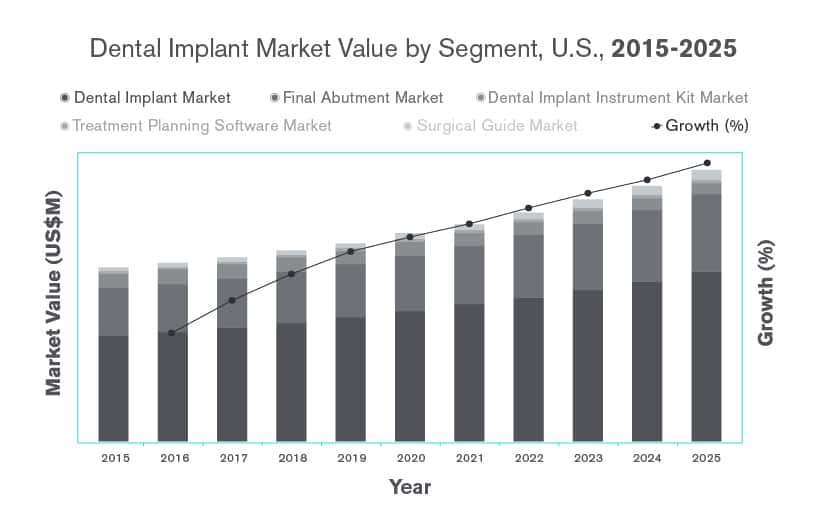

During our extensive R&D capabilities devoted to conduct research with various institutions, which plays a pivotal role in providing ingenious items with added monetary worth. Our foundation of our product’s success relies on our quality control and testing procedures. We offer a wide range of Castable abutments for various systems currently on the market. The wax casting method is commonly used as well as economical to manufacture, while suggesting an asymmetrical casting choice, while taking subtle details into consideration.

The Advantages:

- High abrasion resistance

- Low water absorption

- Low friction incidences

- High-heat resistance

- Exceptional medical grade plastic

- Favorable electrical and dielectric properties

- Exceptional medical grade plastic

- Exceptional casting conditions

- Avoiding residues or sink marks

OUR DATA SHEET: