Digital Dentistry

Digital Dentistry

Explore EM’s CAD/CAM-related portfolios,

And the new ‘state of the art’ of smile perfection.

Digital dentistry and Edison Medical’s CAD/CAM solutions

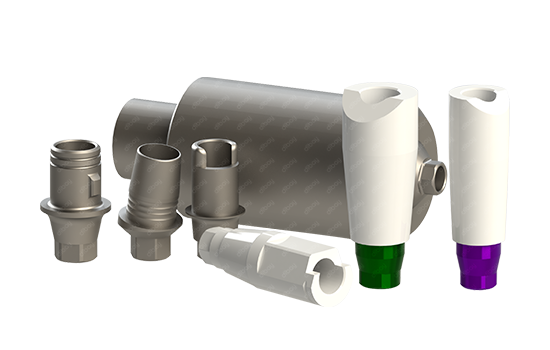

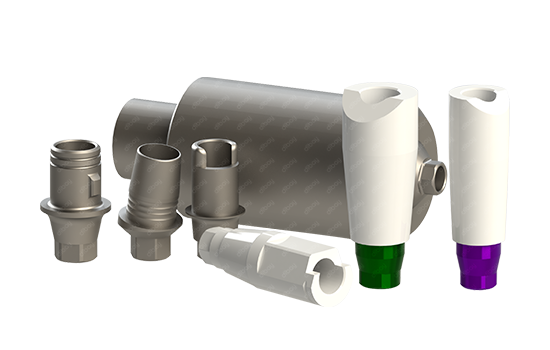

The Edison Medical portfolio of CAD/CAM digital implant dentistry components, including Ti-bases, pre-milled abutments, digital implant dentistry libraries and implant scan body are designed to support a smooth and efficient workflow, with consistent and reliable results. Intelligently designed and packaged parts make their use intuitive, and each component capable of easy integration into the CAD/CAM system your office employs, thanks to Edison Medical’s expansive selection compatible with more than 70 of the market’s leading systems.

CAD/CAM technology raises the bar for dental implantology

CAD/CAM technologies have revolutionized chairside workflows for implantologists across the globe since their introduction to the dental implantology sector. The recent and overwhelmingly positive results from this almost entirely digital implant process have driven a rapid increase in the use of CAD/CAM equipment by dental offices and laboratories.

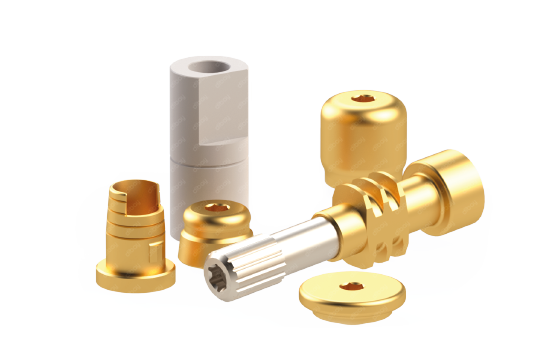

Edison Medical’s Ti-Base portfolio: Bringing digital implant dentistry innovation to the next level

Implementing CAD/CAM technology into the dental implant process renders the digital form of dentistry a world apart from conventional methods. From the ease of taking digital impressions with an oral scanner, to the final customized restoration, the opportunities are abundant.

Utilizing the proper components to construct the restoration is equally important. Our research and development sector has developed two innovative Ti-Bases that are in their final stages before release that give added versatility and functionality to the implant system and restoration process. The unique, patent-pending design will offer the first ever angulated Ti-Base, which drastically improves orientation placement possibilities and provides solutions for even the most compromising edentulous cases.

Check back soon for the release of the Edison Medical Clicq™-Base and Uni-Base™, or sign up for the Edison Medical newsletter to get the latest updates directly to your inbox.

Angulated hex connections are available in two different internal hex orientations (Type A and Type B) that differ by a 30° rotation, creating 12 unique placement options for each Ti-Base abutment.

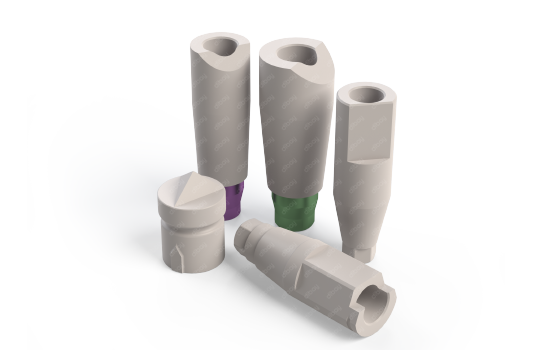

Pre-milled abutments

Edison Medical pre-milled titanium abutments are a one-piece customized solution for digital implant dentistry that are immediately ready for use with your in-house milling equipment. These pre-milled abutments are available for either internal hex or conical connections and are compatible with an extensive range of leading CAD/CAM system manufacturers.

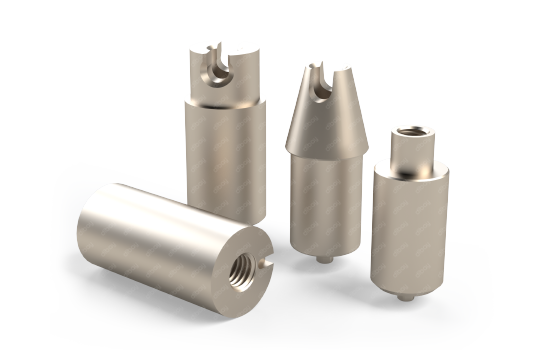

PEEK scanbodies

Edison Medical offers a range of scanbodies made exclusively from the high-grade thermoplastic polymer material PEEK (polyetheretherketone), whose non-reflective, grey-opaque nature aids in overcoming scattered reflection issues during the capture of 3D digital images and is thus is an ideal material for the purpose of digital dentistry intraoral scans. Scanbodies are available for use with a variety of major CAD/CAM system manufacturers, as well as with the Edison Medical Multi-Clicq™ and Clicq™-Base systems.

CAD/CAM system compatibility

Edison Medical’s CAD/CAM Ti-bases, PEEK scanbodies and pre-milled abutments are compatible with over 70 CAD/CAM brands and systems, including Straumann®, BioHorizon®, Megagen®, Nobel Biocare®, Zimmer® and more.

Digital dentistry advantages as a single-visit, chairside treatment

The possibilities that digital dentistry has given to the dental implant industry has made nothing short of ground-breaking progress in the way we place implants. The once arduous task of taking a conventional impression is rapidly being replaced with digital impressions, which can be completed quickly, easily, and smoothly with minimal to no discomfort.

In that same visit, with digital impressions in hand and in-house milling equipment on-site, a restoration can be placed and the patient can walk out of the office with a new prosthetic -- never once having to worry about reduced mastication abilities or esthetics.

The normally multiple-visit process can be reduced to a single visit not only for individual restorations but for full-mouth restorations, as well. Patients are overwhelmingly satisfied with the speedier process, as they not only have to take less time off from work for appointments, but they can avoid more than necessary anesthetization. Immediate restoration placement also means they don’t have to fuss with a temporary prosthesis while waiting for their final restoration.

Digital dentistry technology has not only increased efficiency chairside but has exponentially increased the precision of the entire restorative process, implementing intraoral scanners whose 3D occlusal surface reconstructions are considerably more accurate than the results obtained from conventional impressions. With CAD/CAM technology, dental professionals are capable of an array of restorations with a few clicks, from crowns and veneers to onlays and inlays.

Material choices are also abundant with in-house milling equipment, with the possibility of both polychromatic and monochromatic blanks including nanoceramics, composite resins, high-strength ceramics, polymers and more -- all allowing the implantologist to create a high-functioning, high-quality esthetic restoration in a fraction of the time.

Current limitations of digital dentistry systems

Digital implant dentistry’s leaps and bounds towards a more efficient, precise form of dental restoration does have some caveats. For dental professionals looking to acquire the digitalization tool, scanner, and processing software, but have all milling done at an external laboratory facility, the cost is nevertheless significantly higher than the equipment required to carry out conventional, non-digital impressions and restorations.

For those professionals who desire to set up an in-house milling laboratory in their office, a significant initial investment is required. Regardless of the setup aimed for, any members of your dental team who will be using the CAD/CAM instruments and equipment will need to undergo an extensive amount of training -- yet another investment of money and time.

The initial release of CAD/CAM technology offered an almost entirely closed-architecture, fully proprietary system, meaning that dental professionals needed to choose the system they wanted to work with, and were locked to that system for any future purchases, which provided an ongoing revenue to that supplier. No compatibility meant full dependence on a single company after the initial purchase. Today, most systems are open-architecture, allowing for the cross-use of different systems and providing a wealth of opportunity for restoration fabrication and design.

What is a digital dentistry?

Digital dentistry is dentistry that employs the use of digital dental technology. An example of this is using CAD/CAM (computer-aided design and computer-aided manufacturing) technology to take digital impressions, which can then be used to design and manufacture an implant prosthesis.