The background and history of MegaGen®

MegaGen® is a South Korean dental instrument and equipment manufacturer specializing in full restoration systems. Established in 2002 under CEO Kwang-Bum Park, the company has expanded rapidly over its almost two decades of operation and is currently revenuing around $25 million annually. Expansion was aggressive from the getgo with MegaGen®; the company’s foundations were laid and developed by dental industry professionals and the initial years of existence were dedicated to expanding into the US market with FDA approval of a range of implant systems. The company’s attractive prices and comprehensive offerings played a significant role in its rapid rise in popularity across the globe. In addition to its South Korean headquarters, MegaGen®’s presence in more than 100 countries is supported by their 90+ distributors and 12 affiliates.

MegaGen® dental implant systems

MegaGen® is a company that was founded and developed by dental professionals and because of that the company’s goal has always been to provide a comprehensive restoration solution, from implant to prosthetic. MegaGen® is most well known for their two implant systems: AnyRidge™ and AnyOne™. Both of these MegaGen® dental implant systems have a conical connection, are suitable for multi-unit implant restorations, and are CAD/CAM-compatible, providing lots of prosthetic options and making the AnyRidge™ and AnyOne™ systems highly compatible and versatile when considering restoration options.

The AnyRidge™ and AnyOne™ implant surface

MegaGen® treats the surface of AnyRidge™ and AnyOne™’s titanium implants with its unique XPEED® patented treatment that hydrothermically incorporates calcium ions into the implant surface using sandblasted, large-grit, acid-etched (SLA) treatment. The nanostructure (CaTiO3) of the resulting implant surface is highly efficient in accelerating osseointegration and activating osteoblasts, which not only aids in post-surgical healing around the implant site, but also contributes to the implant’s secondary stability.

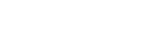

AnyRidge™ and AnyOne™ implant threads

In addition to their unique surface treatment, MegaGen® dental implants also feature a patented threading system: KnifeThread®. This threading system is designed for implants that have similar core diameters and differ only in their thread depth. KnifeThread® features a self-tapping design and thread depths can be selected based on the type of bone in which the implant is to be seated. For hard bone implants, shallower threads are used, while deeper threads are used for increased stability in soft bone. The self-tapping element of the threads further aid stability, and is especially of use in scenarios where the bone is compromised.

The difference between AnyRidge™ and AnyOne™ implants

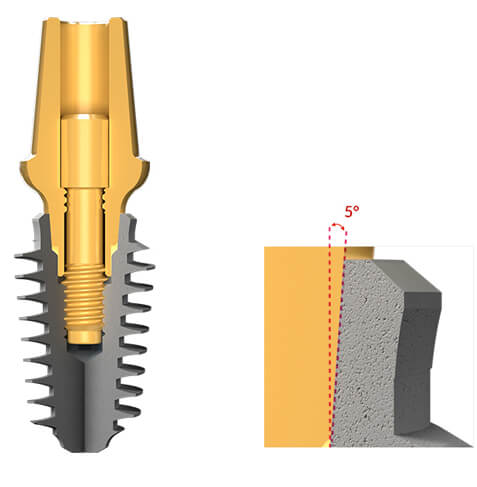

While these two MegaGen® dental implants have a lot in common, they are divided in the type of restoration scenario they are intended for. MegaGen® AnyOne™ is more of an ‘all-around’ implant for ‘anyone,’ designed for use in simple and straight-forward restorative scenarios with predictable initial stability. The AnyOne™ implant cuff is treated with a zirconia nitrate (ZnN) coating that creates improved esthetics in the final restoration. The MegaGen® AnyRidge™ is the more popular of the two implants and is designed for more trying restorations where bone or tissue around the implant site may be compromised and secondary stability is of concern. The change in implant geometry that addresses these more trying restoration scenarios lies predominantly in the implant-abutment connection. The AnyRidge™ is more tapered than the AnyOne™ system, has a smaller diameter, as well as a smaller degree of angulation (5° rather than AnyOne™’s 11°). This 5° connection of the AnyRidge™ can increase the separation force due to cold welding by up to 40%. While both implant systems have an S-line abutment cuff, AnyRidge™ also features a slimmed implant screw cuff, which when combined with the S-line abutment cuff creates a double offset that promotes soft tissue volume and ultimately leads to improved esthetics of the gingival line. When it comes to alternative brand options to integrate into these implant systems, MegaGen®’s AnyRidge™ compatibility is considerably lower than AnyOne™ despite it being the more popular line, most likely due to its more complex coronal design. Edison Medical is one of the few dental implant manufacturers and suppliers of implant components for both lines.

The challenges of MegaGen® AnyRidge™ and AnyOne™

There are two elements of MegaGen®’s implant systems that cause them to occasionally be problematic. The first is the morse taper connection that both systems feature. With this connection, the implant and abutment are cold-welded together, creating an impervious, hermetic seal. While this feature is ideal for implant stability, as well as prevention of microbial leakage that can lead to infection, it also means the implant system can be difficult to work with. The cold weld seal can form a locking connection between implant and abutment before the abutment is even screwed in, which may require a special tool for extraction. The second issue with these MegaGen® dental implant systems is the universal connection size for all implants. In the case of a restoration with a wide-diameter implant, the connection will be significantly smaller, which poses risk of instability, micromovements, loosening and potential subsequent breakage. In this manner the MegaGen® implant design can be somewhat limiting in restoration options that can persist over time.

Edison Medical has the right fit for MegaGen® implants

Edison Medical offers a range of restoration components manufactured for precise fit with MegaGen®’s different implant system lines, including a range of components that have MegaGen® AnyRidge™ compatibility, which is a rare find among dental implant suppliers. In addition to EM’s Pop-Clicq™ line and its range of straight and angled abutments and abutment sets for multi units, Edison Medical has a selection of CAD/CAM Ti-Bases, overdenture attachments, impression copings and more — all for use with MegaGen®’s implant lines. For superior innovation and ingenuity in across-brand functionality, Edison Medical is paving the way for an interchangeable future of dental implants that preserves the highest quality of each brand, including MegaGen® implant systems.