The process of Implant Impression Coping consists of replicating the dental implant position in the mouth, creating a copy of the precise shape

Dental Lab & Impression Copings

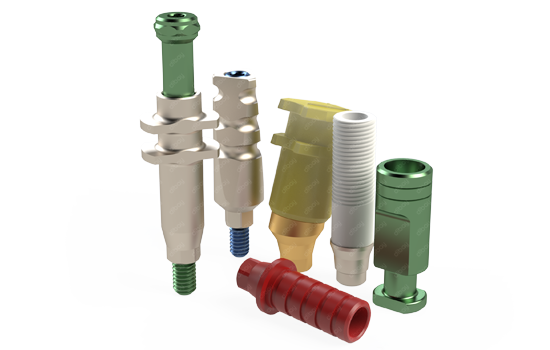

Dental Impression Copings and Lab Components

Always arrive to work prepared.

- SHOP BY CATEGORY -

Components that stand apart

Leave quality assurance to us. A dental lab stocked with the right components is like a well-oiled machine, and that machine runs smoothly when you choose Edison Medical lab and impression components.

The Edison Medical formula for exceptional quality components is simple: the finest grade raw materials, intuitive design for ease of use, meticulous and unrushed production protocols, and rigorous testing and inspection to guarantee product functionality, resilience and longevity.

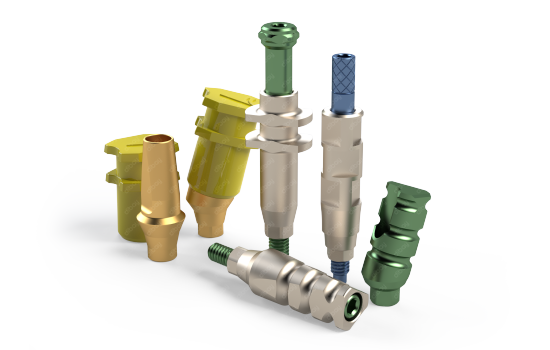

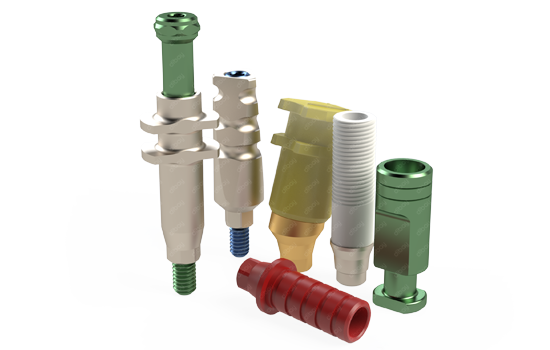

EM’s impression coping and lab component portfolio

The Edison Medical portfolio of impression copings, lab analogs, and castable and UCLA abutments are intended to fulfill the needs of every dental implantologist, dental technician and implantology laboratory — both for stand-alone labs, as well as in-house.

Edison Medical offers lab analogs and dental implant impression copings for both conventional and digital impressions to keep you covered no matter your choice of impression-taking technique or system. All of EM’s components feature across-brand usability with a multitude of implant brands and systems, so you never have to change up your current laboratory situation or seek out alternatives or substitutes.

Lab analogs

Choose implant and abutment analogs for every conventional and digital scenario, all milled from premium quality titanium and anodized for color coding purposes. The Edison Medical lineup of dental lab analogs is compatible with a wide range of implant systems, including major brands such as Neo Biotech®, Osstem®, Hiossen®, Astra® and Megagen®. Uniquely designed lab analogs are also available for each of Edison Medical’s exclusive Clicq™ systems: Clicq™ Pression (transfer abutments), Pop-Clicq™ (individual abutments), Multi-Clicq™ (multi-unit abutments) and Clicq-Base™ (two-piece Ti-Bases).

Impression copings

Impression coping precision is crucial to restoration design, and the shape, position and dimensions of the final restoration depend on that precision. Edison Medical’s range of impression copings are available in a variety of lengths and diameters, along with various open-tray, closed-tray and pick-up transfers, allowing you to select the necessary pieces to create a customized and precise restoration for each patient’s individual prosthetic scenario. Both straight and angled impression copings are also available for cases in which angulation correction is necessary.

Angled impression copings are available with 15° and 25° angulation options for conventional copings, as well as for Edison Medical’s patent-pending Clicq™-Pression line, whose impression transfer poses both as the impression coping and as the final abutment.

All of Edison Medical’s impression copings are milled from premium quality titanium and treated with titanium nitride (TiN) to yield a tough, abrasion-resistant coating that extends the fatigue life of the coping. Edison Medical offers both closed and open tray impression copings, allowing for the most accurate impressions possible.

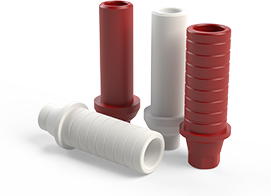

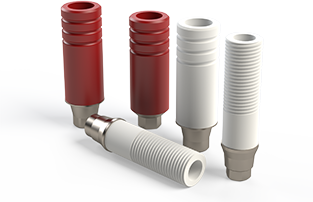

UCLA and castable abutments

Edison Medical’s portfolio of castable and UCLA abutments are used by many professionals as a more cost-effective alternative to gold UCLA and cobalt-chrome pre-milled abutments. With the use of injection molding technologies, the burnout products in both Edison Medical’s standard and UCLA abutments are manufactured to have a high-quality surface finish. With a base material of polyoxymethylene (POM), the burnout process is carried out with no residual debris after melting.

The standard Edison Medical castable abutment is made entirely of POM, while the UCLA abutment lines feature a metal base, either of titanium or cobalt-chrome, which offers improved durability and strength.

The importance of using the proper impression coping

The two types of impression systems, open and closed, have impression copings unique to each system. Despite this, dental technicians have been known to interchange them, using closed impression copings with open impression trays, and open impression copings with closed trays.

This can cause issues not only during the impression taking procedure, but particularly in the dental lab. Using closed impression copings in an open system can lead to vertical inaccuracy, while using open impression copings in a closed system can damage the impression material.

This damaged impression material can lead to dental technicians and laboratory staff experiencing difficulties and inaccurate results in the laboratory when pouring up the model. These technicalities have driven industry professionals to turn to digital solutions, including digital impressions, which save a significant amount of time and money.

What is a dental lab component?

Dental lab components are components which are used by a dental laboratory to construct a restoration. These include single- and multi-unit analogues and transfers, abutment and transfer screws, cast crowns, retainers, fixed and removable prosthetics, impression posts, scan bodies and more.

Blog

- 21.05.2018

- 09.08.2018

Implant Analogs are used by dental lab technicians to position of the dental implant in the patient's mouth.