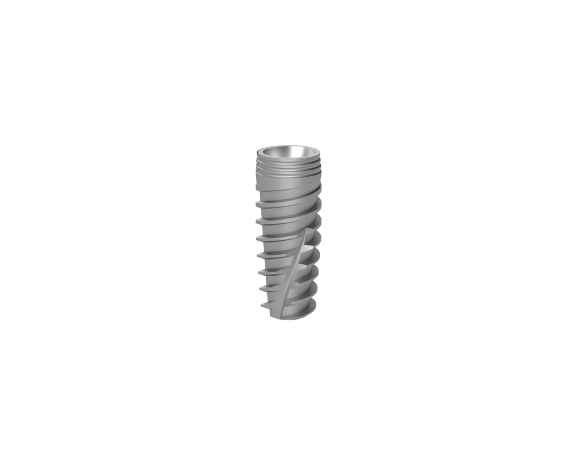

Implant Analogs are used by dental lab technicians to position of the dental implant in the patient's mouth. This procedure is done by impression coping, by making a mold.

The analogs are then screwed into place which then assists in creating a cast for the final product.

The dental analogs provide a precise and fixed point of reference for the platform which the dental technician can shape and place the dental abutments to then create the bridge or crown for the dental implant.

It is of utmost importance to choose a premium quality dental implant analog, as the analog is specifically designed to replicate the internal and external qualities of the final chosen dental implant, as well as it’s exact positioning within the mouth.

Most dental implant analogs are produced from Stainless Steel.

Recently, however, the use of Titanium based analogs has been put into play. Not only does Titanium have attributes that some may say outweigh that of other metals, it is possible to grant them an anodized coating.

Stainless steel has been used since the early 1900’s for surgical uses, most of which started mostly in the orthopedic spectrum. Stainless steel has since been used to replace biological tissue or as a means to help stabilize bone structures as a means to assist in the healing process.

One of the biggest advantages when using stainless steel is it’s high resistance to corrosion when coming into direct contact with biological fluids. This is obviously crucial as corrosion could cause infections as well as further complications.

As opposed to stainless steel that has be in medical use for a very long time, Titanium is rather new to the world of dental implants.

Titanium has one very prominent advantage over that of the stainless steel, which is its strength. Although it retains as much strength as that of steel it is about 50 percent lighter which makes it a far more obvious choice for dental implants.

Titanium Vs. Stainless Steel:

-Titanium has proven to be as strong as other metals, such as Stainless Steel, however is exceedingly lighter in weight.

-Titanium has a high resistance to repetitive loads

-Titanium is far less rigid which prevents less stress on the bone structure.

-It is less likely to generate an immune response due to it being resistant to corrosion.

-Titanium is by far more Biocompatible as well as osseointegrated.

Due to these qualities, it is of utmost importance to produce dental analogs at the highest quality, as they are what defines the quality of the final dental implant with the most precise fit and tolerance.

Here at Edison Medical™, we make sure that our dental implant analog are produced of the finest quality materials, that they undergo rigorous inspection and comply with International regulatory quality control and standards.

We provide a wide range of Premium Quality Implant analogs and replicas which are compatible with the leading brands on the market.

We place great emphasis on high quality analog, as it is of utter importance and the key to a successful outcome and a very happy patient.