Pinpointing Quality

We all know that for every tool on the market, there is a wide variety to choose from, and sometimes it’s not easy to buy smart. Dental implant tools are produced in many locations around the world, and standards of quality can vary drastically between them. While we work our hardest at Edison Medical™ to provide our clients with the most competitive prices in the market, we would never sacrifice the quality of what we make to do that. So how can you identify a high quality product? Easy.

- Check the quality of the raw materials used. At Edison Medical™, we use AISI 400 Series stainless steel. Our stainless steel goes through precipitation hardening after machining, followed by electropolishing and passivation that prevents any rusting of our tools caused by cleaning solutions and sterilization.

- Where was the product made? We at Edison Medical™ go straight to the source for high quality steel: Germany. Germany is the world’s seventh largest steel production, with manufacturing making up more than a quarter of its economy. The country’s reputation for quality-made steel goes back centuries. Our vote of confidence towards German steel led us to manufacture our steel tools there.

- Are you buying from a company you trust? Forming a trustful relationship with your supplier takes a lot of stress out of the purchasing process for you. We do all of the legwork to ensure you are getting the highest quality product, and at Edison Medical™ we stand behind all of our products.

A Tool Every Dentist Should Have

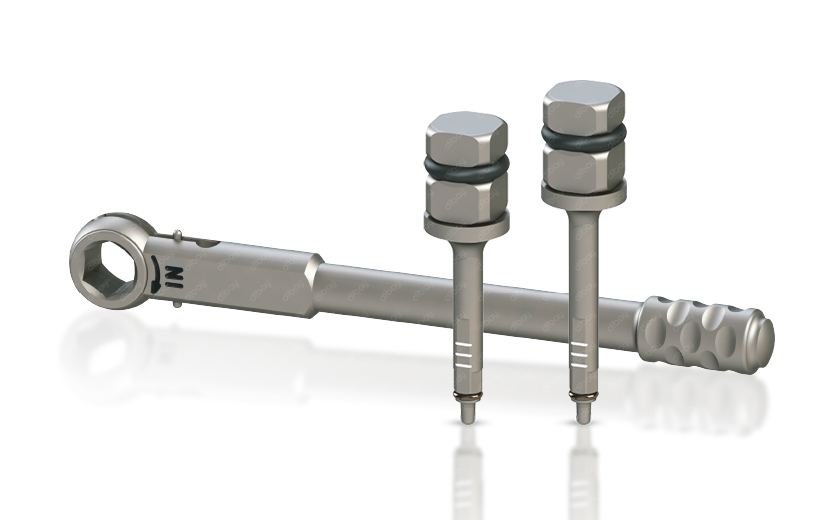

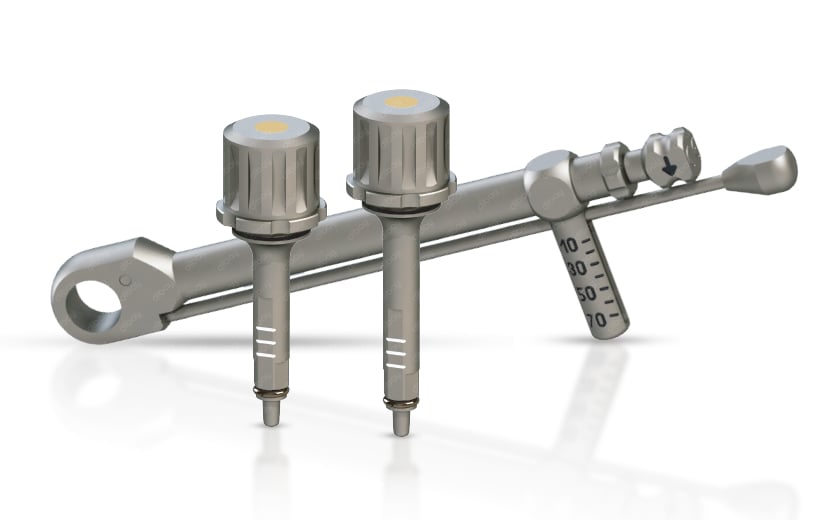

Now that we’ve identified how to stay away from lower quality products, let’s focus on why an implant torque wrench is a tool that every dentist should have in his/her tool belt.

Within an implant system, abutments are often fixed to the implant with a screw. The fundamentals of screw mechanics define the abutment and implant together as the screw joint, the two parts being held together by a screw. The tightening of the screw drives it to elongate, which produces tension. This tension is countered by elastic recovery, which in turn pulls the abutment and implant together, creating a clamping force. So, the opposing forces, of the screw, pulling the joint apart, and the elastic recovery binding its two parts together, must be equal, otherwise, screw loosening can occur. How can we prevent this from happening?

By using an implant torque wrench, which allows us to specify the torque at which we want to tighten our screw, we can accurately form our screw joint within our implant without excessive force in either direction. This allows our prostheses to remain secured in place during daily use by the patient. All of this is achievable in the least invasive way possible, which is significantly more comfortable for the patient and for the dentist.

Accuracy of Your Implant Torque Wrench

Accuracy of torque, while normally within 10% of the target torque value, can waver with time and clinical use of these wrenches. Therefore, it is recommended that these tools be checked on a regular basis to ensure that they remain within their target torque values, as well as recalibrating them annually.

Check out our torque wrenches and ratchets in the Edison Medical™ online Platform.